Top 10 Rubber Pump Impellers What You Need to Know

In the fluid handling industry, the choice of a Rubber Pump Impeller is crucial. Reports indicate that impeller selection can impact pumping efficiency by over 20%. Rubber pump impellers are widely used due to their durability and resistance to wear. Specifically, they excel in handling abrasive materials.

However, not all rubber impellers perform the same. Quality varies significantly among manufacturers. According to a study by the Pump Manufacturers Association, improper selection can lead to increased maintenance costs by 15% annually. This raises concerns about long-term reliability.

Knowing what to look for in a Rubber Pump Impeller can make a difference. Material composition, design, and compatibility matter. Investing time in research is essential. Understanding your specific application will help in choosing the right impeller for optimum performance.

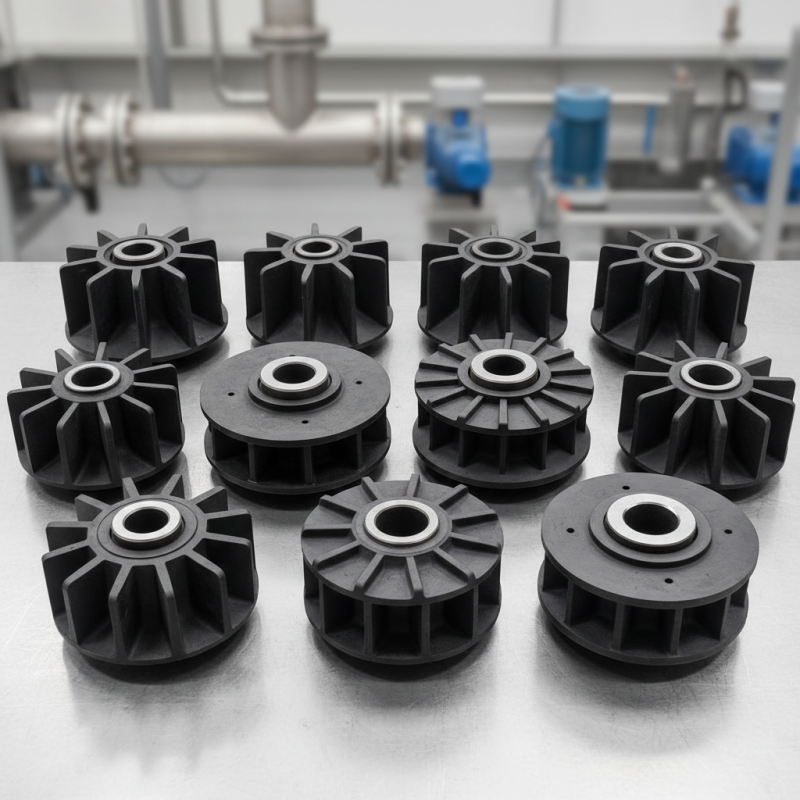

Overview of Rubber Pump Impellers and Their Importance

Rubber pump impellers play a critical role in various pumping systems. They are designed to propel fluids efficiently and effectively. These components are essential in applications ranging from industrial processes to agricultural irrigation. The selection of the right rubber impeller can significantly impact performance and longevity.

One key advantage of rubber impellers is their flexibility. They can handle a variety of fluids, including corrosive chemicals. This versatility makes them suitable for diverse environments. However, not all rubber impellers are created equal. Factors such as temperature and fluid composition can affect their performance. Choosing the wrong type can lead to severe wear and premature failure.

The importance of regular maintenance cannot be overstated. Inspecting rubber impellers for wear and tear is crucial. A worn impeller may not perform as expected, leading to inefficiencies. While rubber impellers are durable, they require thoughtful care. Learning from past mistakes can guide better decisions in the future. Understanding the specific needs of your application will ensure optimal results.

Key Materials Used in Manufacturing Rubber Pump Impellers

Rubber pump impellers play a crucial role in fluid movement. They are designed to efficiently transfer liquids in various industries. The materials used for manufacturing these impellers significantly affect their performance. Common materials include natural rubber, synthetic rubber, and thermoplastic elastomers.

Natural rubber offers excellent elasticity and abrasion resistance. It provides a good grip, ensuring efficient fluid flow. However, it may not resist certain chemicals well, which can limit its use. Synthetic rubber, on the other hand, is engineered for specific applications. It can withstand harsh chemicals and extreme temperatures. This versatility makes it a preferred choice in many environments.

**Tip:** When selecting an impeller, consider the operating environment. The right material can enhance longevity and performance.

Thermoplastic elastomers are gaining popularity due to their lightweight and flexible nature. They can be molded into complex shapes, making them adaptable. However, not all applications require this level of flexibility. Some operations may benefit from more rigid materials.

**Tip:** Evaluate the specific requirements of your pump system. Look for a material that balances durability and flexibility.

Top Characteristics to Consider When Choosing an Impeller

When selecting a rubber pump impeller, several key characteristics should guide your decision. Material quality is crucial. Rubber impellers should be durable and resistant to wear. Look for options that can handle various fluids without degrading quickly. A good impeller also ensures proper sealing to prevent leaks, which can lead to operational issues.

Sizing matters greatly too. An improperly sized impeller can lead to inefficiency. It may either underperform or overload your pump. Checking compatibility with your system is essential. Remember, not every impeller fits every pump.

Consider the design of the impeller. A well-designed impeller can create optimal flow and pressure. If it’s built poorly, you may see inconsistent performance. There should be a balance between rigidity and flexibility. Too much of either can lead to failures.

Finally, don’t overlook maintenance. Some designs require more upkeep than others, which can affect your overall efficiency. The right choice isn’t always clear. It's an ongoing process of evaluation.

Comparison of the Best Rubber Pump Impellers in the Market

When selecting rubber pump impellers, the market offers various options. Studies show that the right choice can enhance efficiency by up to 20%. Material quality plays a critical role. The composition of rubber affects durability and performance. Some impellers degrade faster under certain environments. It’s essential to examine environmental factors before purchasing.

Performance metrics are vital. Impeller design influences flow rates significantly. Reports indicate that well-designed impellers can achieve up to 80% hydraulic efficiency. However, a poorly crafted impeller might only reach half of that. This gap emphasizes the need for precise engineering. Regular testing and review of performance data are crucial in this field.

Cost varies widely among rubber impellers. Budget-friendly options may lack quality and longevity. Sometimes, higher-priced models use advanced materials, providing better resilience. Many users still find it challenging to balance cost and performance effectively. This ongoing struggle reveals a need for continuous market research. Making informed decisions in this area remains essential for success.

Top 10 Rubber Pump Impellers Performance Comparison

This chart compares the flow rates of the top 10 rubber pump impellers available on the market, showcasing their performance in gallons per minute (GPM). This information can assist users in selecting the right impeller based on flow capacity.

Maintenance Tips for Extending the Life of Rubber Pump Impellers

Rubber pump impellers are essential in maintaining fluid flow. However, they can wear out quickly if not properly cared for. Regular maintenance can significantly extend their lifespan and improve performance.

One key maintenance tip is to inspect the impeller regularly. Look for signs of wear or damage, such as cracking or erosion. Ignoring small issues can lead to larger failures later on. Additionally, ensure the impeller is clean. Debris build-up can hinder performance and increase strain on the pump.

Another important aspect is lubrication. Make sure that the impeller's moving parts are correctly lubricated. This reduces friction and heat buildup. Remember, excessive heat can accelerate wear and lead to premature failure. Also, be mindful of operating conditions. Pumps running at high temperatures or pressures may need more frequent checks. Regular maintenance helps prevent unexpected breakdowns.