Top 10 Material Lifting Equipment You Need to Know?

In the world of construction and manufacturing, Material Lifting Equipment plays a crucial role. These tools help move heavy loads safely and efficiently. Knowing the top equipment available can greatly enhance workflow and productivity.

Many companies rely on cranes, hoists, and forklifts. Each type serves a unique purpose, catering to specific needs. However, selecting the right equipment can be challenging. Misjudgments in choices may lead to inefficiencies or even workplace accidents. It's vital to understand the strengths and weaknesses of each option.

Investing in quality Material Lifting Equipment offers more than just convenience. It can lead to better safety records and improved project timelines. Yet, even with the best tools, proper training is essential. Equipment alone does not guarantee success; it's how we use it that truly matters.

Top 10 Material Lifting Equipment: Overview of Industry Standards

Material lifting equipment plays a crucial role in various industries. Understanding industry standards ensures safety and efficiency. These standards provide guidelines on how to use and maintain equipment properly. For example, the load capacity must always be clearly indicated. Each piece of machinery may have unique specifications that operators must follow.

The importance of training cannot be overstated. Operators should be well-prepared to handle lifting equipment. Improper use can lead to accidents or equipment failure. Regular inspections and maintenance are necessary. Equipment must be checked for wear and tear. Neglecting minor issues can escalate into significant problems. It’s essential to take these matters seriously.

Additionally, knowing the specific requirements for different equipment types is vital. Forklifts, hoists, and cranes all have their own regulations. Confusion often arises from a lack of clarity about these standards. Reflecting on potential gaps in knowledge can improve overall safety. Awareness and adherence to industry standards not only protect workers but also enhance productivity in workplaces.

Key Specifications and Load Capacities of Cranes in Material Lifting

When considering cranes for material lifting, it's essential to understand key specifications and load capacities. Cranes come in various types, including overhead, mobile, and tower cranes. Each type serves specific purposes and industries, affecting their load capabilities. For instance, mobile cranes typically hold between 10 to 80 tons, while tower cranes can lift over 20 tons. These figures indicate that choosing the right crane involves evaluating your lifting requirements.

Load capacities can vary significantly based on the crane’s design and construction. A report from the International Crane and Transport Association highlighted that operational safety often corresponds with load ratings. Inadequate capacity can lead to accidents. It's crucial to weigh the benefits of high-capacity cranes against their complexity and potential maintenance costs. Operators may overestimate what their equipment can handle, leading to dangerous situations on site.

Further complicating choices, user experience plays a role in crane operation efficiency. A study found that cranes operated by less experienced personnel often underperform their designed capabilities. This highlights the need for proper training and adherence to safety protocols. Understanding these nuances can help ensure that the right crane is selected and utilized effectively.

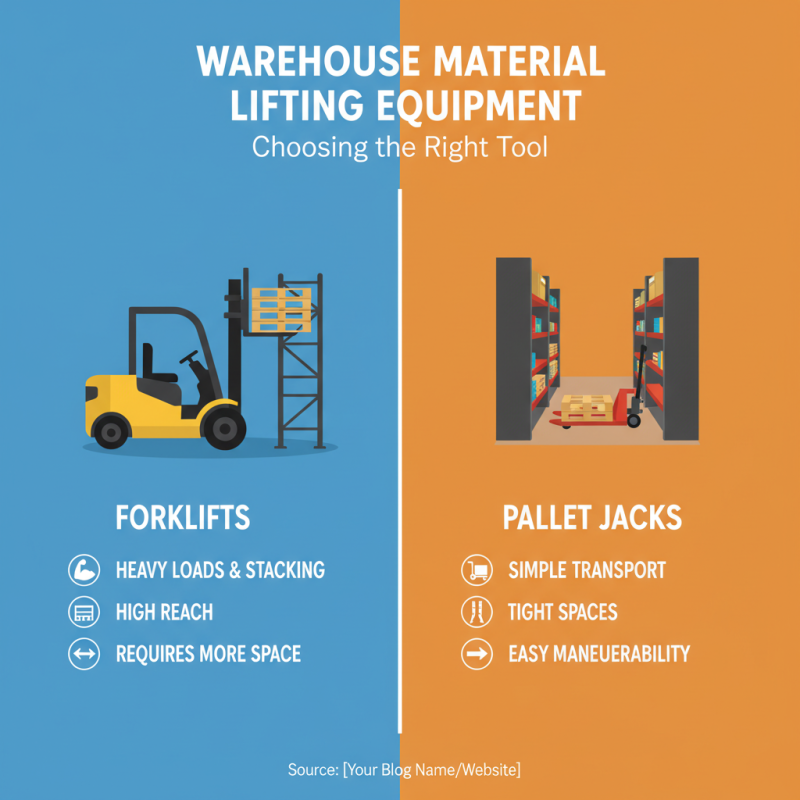

Comparison of Forklifts vs. Pallet Jacks in Warehouse Operations

In warehouse operations, choosing the right material lifting equipment is crucial. Forklifts and pallet jacks are two popular options. They serve different purposes and environments. Forklifts can lift heavy loads and are useful for stacking. However, they require more space to operate effectively. In contrast, pallet jacks are easier to maneuver in tight spaces. They are ideal for simple transport tasks.

When using forklifts, safety is key. Always check the load limits and ensure the area is clear. Operators should be trained and certified. Misuse can lead to accidents. Pallet jacks, while safer, also require attention. Ensure the wheels are free from debris. It's easy to overlook maintenance.

Tips: Regular inspections of both equipment types will reduce breakdowns. Encourage your team to report any issues immediately. A small problem can escalate quickly if ignored. Communicate regularly to ensure all team members understand equipment limitations. Make adjustments as needed based on workload and space constraints.

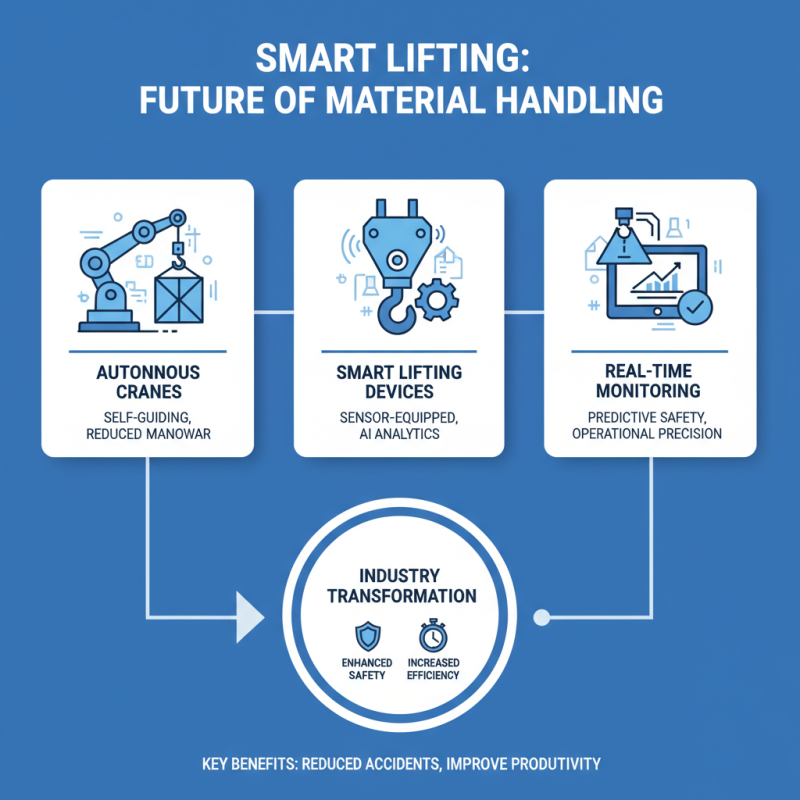

Emerging Technologies in Material Lifting Equipment: Trends and Future

Emerging technologies in material lifting equipment are transforming the industry. Innovations like autonomous cranes and smart lifting devices are gaining traction. These technologies enhance safety and efficiency. With sensors and AI, operators can monitor loads in real-time. This reduces the risk of accidents and improves operational precision.

Investing in automation can seem daunting. Many companies hesitate to adopt new technologies. However, the benefits often outweigh the challenges. Lifting equipment with integrated safety features can prevent costly mistakes. TIP: Regular training on these new tools is crucial for all operators.

Sustainability is another crucial trend. Electric-powered lifting devices are becoming more popular. They offer a greener alternative to traditional equipment. Adopting such technologies can attract eco-conscious clients. However, the transition requires careful planning. Older machines may need upgrades to support new systems. TIP: Assess your current equipment before making changes. Reflection on capabilities can guide smarter investments.

Safety Standards and Regulations for Material Handling Equipment Usage

When it comes to material handling, safety standards are paramount. Equipment must comply with regulations to protect workers and ensure efficiency. Operators should be trained on the specific equipment they use. This training often covers safe operation, weight limits, and emergency procedures. Identifying hazards is a part of this training too. Sometimes, overlooked details can lead to accidents.

Regular inspections of the equipment are crucial. Defects may remain unseen until it’s too late. A thorough understanding of the equipment’s specifications helps. Checking for worn cables or malfunctioning controls is vital. Periodic maintenance can extend the life of the equipment and enhance safety. However, it's common for teams to neglect these tasks due to busy schedules.

Each worker should wear appropriate personal protective equipment. This simple step can significantly reduce injury risks. Yet, adherence to safety protocols can sometimes be inconsistent. Awareness campaigns can help reinforce the importance of these practices. Encouraging a culture of safety is essential. Everyone plays a role in maintaining a safe work environment. It’s a continuous process that demands collective effort and vigilance.

Related Posts

-

China's Smart Manufacturing: The Global Leader in Quality Material Handling Lifts

-

How to Choose the Right Material Lift for Your Construction Project Needs

-

Discovering Quality Suppliers for Best Material Handling Systems with Proven Strategies

-

Exploring the Future of Material Lifting Equipment Technology Trends and Their Global Impact in 2025

-

7 Key Advantages of Using the Best Material Handling Cart for Your Business

-

How to Identify the Best Manufacturers for High Quality Material Handling Supplies