Innovative Solutions for Optimizing Material Handling Equipment Efficiency

In the rapidly evolving landscape of logistics and supply chain management, optimizing Material Handling Equipment (MHE) efficiency has become a key priority for organizations aiming to enhance productivity and reduce operational costs. According to a report by the Material Handling Industry of America (MHIA), over 50% of material handling costs are tied to equipment-related inefficiencies. As businesses strive to meet the growing demand for faster and more reliable service, innovative solutions such as automation, real-time data analytics, and improved ergonomic designs are being implemented to transform traditional workflows. By leveraging these advancements, companies can not only streamline their operations but also significantly extend the lifespan of their MHE, ultimately leading to a more sustainable and effective supply chain.

In the rapidly evolving landscape of logistics and supply chain management, optimizing Material Handling Equipment (MHE) efficiency has become a key priority for organizations aiming to enhance productivity and reduce operational costs. According to a report by the Material Handling Industry of America (MHIA), over 50% of material handling costs are tied to equipment-related inefficiencies. As businesses strive to meet the growing demand for faster and more reliable service, innovative solutions such as automation, real-time data analytics, and improved ergonomic designs are being implemented to transform traditional workflows. By leveraging these advancements, companies can not only streamline their operations but also significantly extend the lifespan of their MHE, ultimately leading to a more sustainable and effective supply chain.

Understanding the Importance of Material Handling Equipment Efficiency

In the rapidly evolving landscape of material handling, the efficiency of equipment is paramount to ensuring streamlined operations across various industries. As companies increasingly recognize the significance of optimized material handling, automation has emerged as a crucial factor driving efficiency. The Japanese market for automated material handling equipment is witnessing a remarkable Compound Annual Growth Rate (CAGR) of 9.2% up to 2030, reflecting a growing demand for advanced technologies that reduce manual intervention and enhance productivity.

Furthermore, innovations in artificial intelligence are revolutionizing warehouse management. By optimizing product placement and refining picking patterns during the fulfillment stage, AI technology significantly boosts efficiency. Automated systems not only reduce operational costs but also contribute to safety by minimizing the risk of human error. As organizations invest in sophisticated material handling solutions, the emphasis on training and partnerships with technology integrators becomes more pronounced, ensuring that teams are equipped to leverage new technologies effectively.

This focus on efficiency in material handling equipment will ultimately transform the way businesses manage logistics, paving the way for sustained growth and competitive advantage.

Assessing Current Equipment Performance Metrics and Their Impact

In the ever-evolving landscape of material handling, the efficiency of equipment plays a pivotal role in ensuring seamless operations. To optimize performance, it is essential to assess current equipment performance metrics. This involves analyzing key indicators such as throughput, response time, and energy consumption. By employing data analytics, organizations can uncover patterns that reveal operational bottlenecks and inefficiencies in real time.

Understanding the impact of these performance metrics is equally crucial. Equipment that operates below optimal levels not only increases overhead costs but also affects overall productivity and employee morale. For instance, a conveyer system that frequently breaks down can lead to extended downtime, disrupting the entire supply chain. By regularly reviewing performance data, businesses can implement targeted strategies to enhance the functionality of their material handling equipment, enabling them to achieve higher efficiency rates and ultimately drive greater profitability.

Innovative Technologies Driving Efficiency in Material Handling

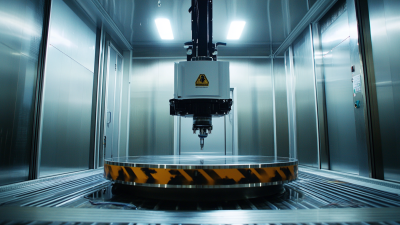

In the fast-paced world of logistics and warehouse management, harnessing innovative technologies is crucial for enhancing the efficiency of material handling equipment. Automation stands out as a game-changer, with advancements in robotics and artificial intelligence streamlining operations. Automated guided vehicles (AGVs) and drones are not only optimizing the transportation of goods but also reducing labor costs and minimizing human error. By integrating sensors and IoT technology, these systems can communicate real-time data, allowing for better inventory management and workflow efficiency.

Beyond automation, augmented reality (AR) and virtual reality (VR) are transforming training and operational processes within material handling. These technologies provide interactive environments for employees to learn the ins and outs of equipment usage without the risk of accidents. Additionally, predictive analytics powered by big data can forecast equipment maintenance needs, further enhancing uptime and operational efficiency. As these innovative solutions continue to evolve, businesses are poised to achieve unprecedented levels of productivity and safety in their material handling operations.

Strategies for Integrating Automation in Material Handling Systems

The integration of automation in material handling systems has become a driving force for enhancing operational efficiency and productivity. According to a report by the Material Handling Industry of America (MHIA), nearly 83% of manufacturers are expected to invest in automation technologies over the next few years. This trend is catalyzed by the need to reduce labor costs and improve accuracy in handling materials, leading to greater overall efficiency. Automated solutions such as Automated Guided Vehicles (AGVs) and robotic picking systems can reduce processing time by up to 30%, thus streamlining operations and minimizing downtime.

Furthermore, the implementation of automation in material handling not only optimizes workflow but also mitigates workplace injuries, which can result in significant cost savings. A study from the National Safety Council shows that organizations that integrate automated systems see a reduction in workplace incidents by approximately 50%. This statistic underscores the dual benefits of increased efficiency and enhanced safety, making automation not just a strategic advantage but also a necessary component in modern material handling operations. Investing in these innovative automation solutions positions companies to thrive in an increasingly competitive market.

Best Practices for Continuous Improvement in Equipment Performance

Enhancing the performance of material handling equipment is crucial for operational efficiency within warehouses and production facilities. One of the best practices for continuous improvement is implementing regular maintenance schedules. Preventive maintenance not only prolongs the lifespan of equipment but also ensures that any potential issues are identified and resolved before they disrupt operations. By adopting a proactive approach, businesses can minimize downtime and maintain a steady workflow, which is essential for meeting heightened customer demands.

In addition to maintenance, utilizing data analytics is vital for optimizing equipment performance. By collecting and analyzing operational data, companies can identify inefficiencies and patterns in equipment use. This insight allows managers to make informed decisions regarding equipment allocation, scheduling, and the need for upgrades or replacements. Furthermore, employee training is another key element; ensuring that staff are well-versed in operating equipment correctly can significantly reduce the occurrence of accidents and equipment malfunctions. Together, these practices create a foundation for ongoing improvements and heightened efficiency in material handling operations.

Innovative Solutions for Optimizing Material Handling Equipment Efficiency - Best Practices for Continuous Improvement in Equipment Performance

| Equipment Type | Efficiency Rate (%) | Downtime (Hours/Month) | Maintenance Cost ($/Month) | Operator Training Level |

|---|---|---|---|---|

| Forklift | 85 | 5 | 300 | Advanced |

| Conveyor System | 90 | 3 | 250 | Intermediate |

| Pallet Jack | 80 | 4 | 150 | Basic |

| Automated Guided Vehicle (AGV) | 95 | 2 | 500 | Expert |

| Stacker Crane | 88 | 6 | 400 | Intermediate |

Related Posts

-

How to Identify the Best Manufacturers for High Quality Material Handling Supplies

-

5 Compelling Benefits of Choosing Vacuum Lifting Equipment for Your Business

-

Ultimate Guide to Choosing the Best Material Handling Solutions for Your Business Needs

-

Innovative Barrel Lifting Equipment Shines at the 137th Canton Fair in Guangzhou

-

7 Essential Insights to Optimize Your Material Handling Efficiency and Reduce Costs

-

Global Market Insights 2025 Trends Shaping the Future of Drum Lifting Equipment