Top Injection Machine Robot Tips for Increased Efficiency?

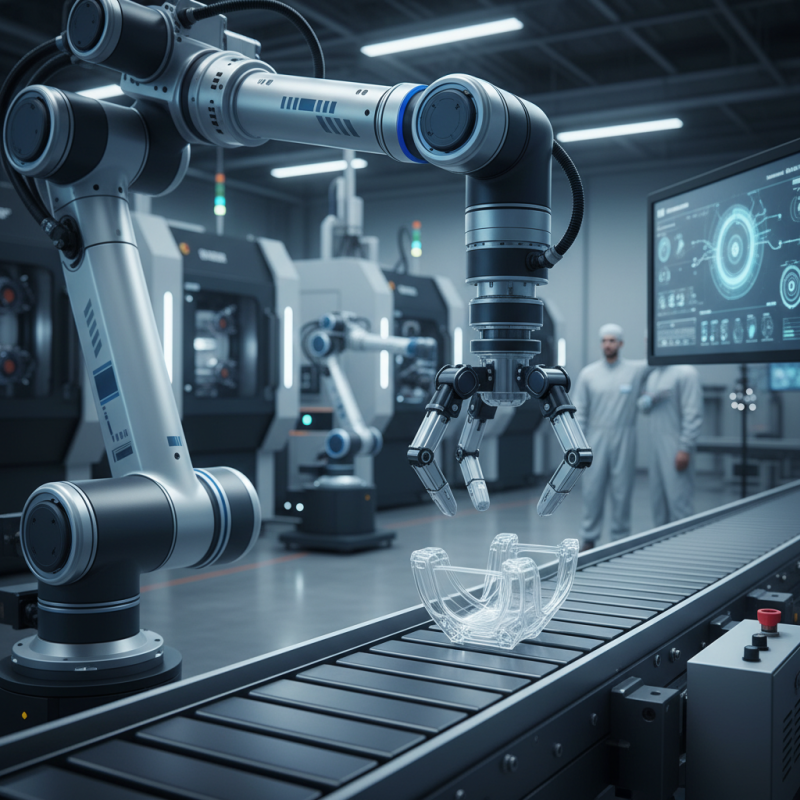

In the world of manufacturing, efficiency is essential. The Injection Machine Robot plays a vital role in enhancing productivity. These robots automate repetitive tasks, reducing human error. However, maximizing their effectiveness requires careful consideration.

Many facilities still face challenges when integrating Injection Machine Robots. Some operators may struggle with programming. Maintenance is often overlooked, leading to decreased performance. Training staff on robotics is crucial but can be time-consuming. Despite these hurdles, the benefits are significant. Improved speed and precision can transform production lines.

Innovation is key in this rapidly evolving field. Companies must remain adaptable. Regular assessments of robot performance can uncover areas for improvement. Small adjustments can lead to substantial efficiency gains. Embracing new technology and training methods is a step forward in maximizing the potential of Injection Machine Robots.

Benefits of Incorporating Robots in Injection Molding Processes

Incorporating robots into injection molding processes has numerous benefits. Robots enhance precision in part production. They can handle repetitive tasks consistently, minimizing human error. This transition leads to reduced waste and improved product quality. Efficiency gains are often noticeable in cycle times as robots can work faster and uninterrupted.

When optimizing a robotic injection molding system, consider the following tips. Ensure the robot is properly programmed for complex tasks. Adjustments might be needed as production demands shift. Regular maintenance of the robotic systems is crucial. A malfunctioning robot can slow down the entire process, creating bottlenecks.

It's important to evaluate the workspace layout. Robots need adequate space for movement and operations. Often, small adjustments can improve efficiency dramatically. Training staff to work alongside robots can also enhance integration. However, it can be a challenge for teams used to traditional methods. Embracing change is necessary for better productivity.

Key Metrics for Measuring Injection Robot Efficiency in Production

Measuring injection robot efficiency requires specific metrics that reflect performance. Key metrics include cycle time, setup time, and throughput. Cycle time measures how quickly a robot completes production cycles. Shorter cycle times indicate better efficiency. Tracking setup time is crucial for understanding delays. Long setups can waste valuable production hours.

To improve efficiency, focus on regular maintenance. A well-maintained robot runs smoother and faster. Frequent checks can prevent costly breakdowns. Additionally, training operators effectively can enhance performance. Operators need to understand the robot's capabilities fully. Sometimes, they overlook potential optimizations in the workflow.

Throughput is a fundamental metric to evaluate. It shows how much product is produced in a given timeframe. Aim for higher throughput but not at the expense of quality. Quality issues can lead to rework and wasted resources. Regularly analyze production data to pinpoint areas needing adjustment. Small changes can lead to significant improvements.

Best Practices for Programming and Operating Injection Machine Robots

Programming and operating injection machine robots require a blend of technical knowledge and practical skills. Start by focusing on your programming language. Many operators overlook updates or advanced coding techniques. A small change in code can significantly enhance machine performance. Regularly revisiting your programming can help identify inefficient loops. This reflection can lead to better robot behavior.

Another essential aspect is the setup of the operating environment. Overcrowded workspaces can lead to mistakes. Keep tools organized and ensure pathways are clear. Often, operators fail to maintain equipment properly. Regular inspections prevent malfunctions, which can save time. In this case, practicing routine maintenance is not just a recommendation; it is a necessity.

Data tracking is crucial for improving efficiency. Many forget to log their machine's performance metrics. Without this data, it’s challenging to identify trends or issues. A simple spreadsheet can help track cycles and downtime. After all, knowledge is power. However, oversights in data management may hinder the optimization process. Regular reflections on both successes and failures can lead to improved practices.

Innovative Technologies Enhancing Robot Integration in Injection Molding

The integration of innovative technologies in injection molding is transforming the industry. Robots equipped with advanced sensors can now perform tasks with remarkable precision. They react instantly to variations in the production process. This capability minimizes defects and enhances product quality. However, not all robot systems are created equal. Some may struggle with specific tasks, leading to inefficiencies that require a reassessment of their roles.

Incorporating AI and machine learning further boosts injection molding efficiency. These technologies allow robots to analyze patterns and optimize operations in real time. They adjust parameters on the fly, aligning production speed with quality control. Yet, implementing these solutions can be complex. Teams may face challenges integrating software and hardware components effectively.

Moreover, a lack of proper training can hinder these benefits. Operators need to understand the technology thoroughly. Continuous learning is essential for maximized efficiency. Even small oversights in programming or system setup can lead to significant downtime. Thus, it's vital to focus on not just the technology, but also on the people who operate it. Balancing these elements can enhance production capabilities while ensuring a more streamlined process.

Top Injection Machine Robot Tips for Increased Efficiency

| Tip | Description | Benefits | Technologies Used |

|---|---|---|---|

| Optimize Robot Paths | Refine the movements to reduce cycle time. | Increased production rates. | Advanced simulation software. |

| Integrate IoT Sensors | Use sensors for real-time data collection. | Enhanced monitoring and maintenance. | IoT platforms, cloud computing. |

| Automate Quality Control | Implement robotic vision systems for inspection. | Consistent quality and reduced waste. | Machine learning, AI. |

| Enhance User Interfaces | Improve operator control systems for ease of use. | Lower training time and error rates. | Interactive software and touch interfaces. |

| Regular Software Updates | Keep robotic systems updated for optimal performance. | Improvements in efficiency and functionality. | Firmware and software enhancements. |

Case Studies: Successful Implementations of Robots in Injection Machines

Robotics in injection molding is on the rise. A recent report states that automation can boost production efficiency by up to 25%. Case studies show tangible benefits for manufacturers. For instance, a facility that integrated a robotic system reduced cycle time by 30%. This change saved them substantial labor costs and increased output.

The key lies in the seamless integration of robots with injection molding machines. In one case, a medium-sized factory replaced a manual loading process. The robot now handles material loading automatically, enhancing speed and consistency. However, not all implementations have been flawless. Adjustments were needed to optimize the robot's movements, which initially caused delays.

Another study revealed that around 40% of factories faced challenges in employee training. Workers needed time to adjust to the technology. Moreover, maintenance of robotic systems can become a learning curve. Budget constraints also posed hurdles in adopting advanced solutions. Refining these processes can lead to better efficiency and lower costs in the long run.