How to Choose the Right Stainless Hex Nuts for Your Projects?

When it comes to choosing the right Stainless Hex Nuts for your projects, many factors come into play. Stainless hex nuts are essential components in construction, machinery, and various DIY tasks. Their durability and resistance to corrosion make them appealing.

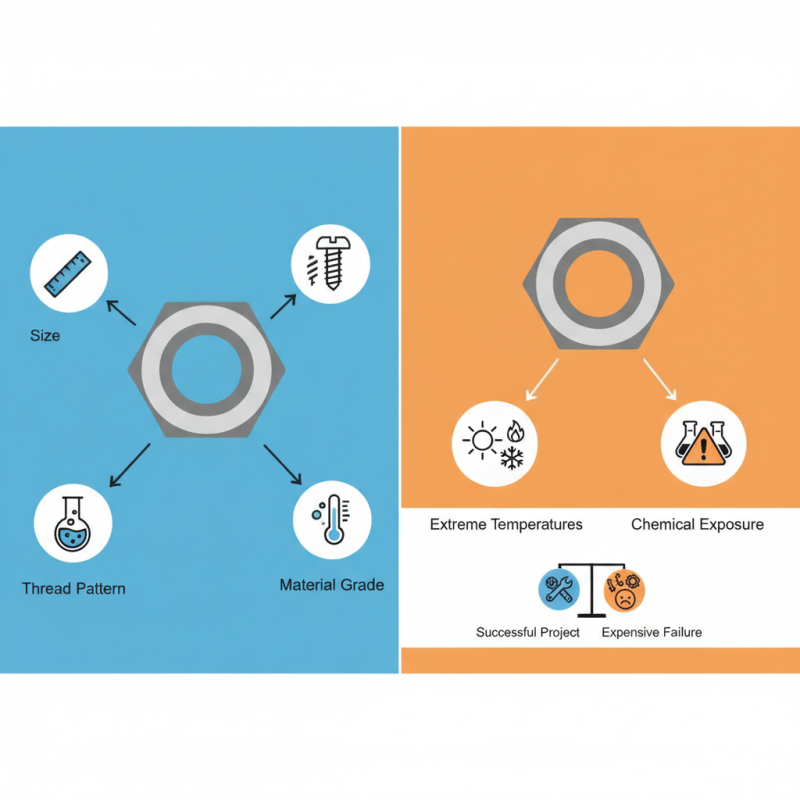

However, selecting the appropriate stainless hex nuts can be challenging. The size, thread pattern, and material grade must align with your specific needs. It’s common to overlook these details, leading to potential issues. For example, using the wrong size may result in a weak connection that fails under stress.

Moreover, it's crucial to evaluate the environment where these nuts will be used. Will they face extreme temperatures or exposure to chemicals? Understanding these aspects can be the difference between a successful project and an expensive failure. Thus, a thoughtful selection process is imperative for long-lasting results.

Understanding the Different Types of Stainless Hex Nuts

When selecting stainless hex nuts, understanding their types is crucial for successful projects. Stainless steel nuts come in various grades, the most common being 304 and 316. Grade 304 is widely used due to its excellent corrosion resistance. However, it may not withstand harsh environments as well as 316. For marine applications, 316 is preferable, as it contains molybdenum, which enhances its resistance to pitting.

Beyond grades, hex nuts are available in different styles. Standard hex nuts are versatile, but lock nuts add an extra layer of security by resisting loosening under vibration. According to a recent industry report, 40% of hardware failures are attributed to insufficient fastening. Using the right lock nut can significantly reduce these failures and enhance project longevity.

Size is another vital consideration. Hex nuts are available in various sizes and thread standards. Choosing the wrong size may lead to unexpected issues, such as stripped threads or loose connections. Be cautious when selecting dimensions. Research shows that incorrect sizing can lead to a 25% increase in repair costs. Understanding the specific needs of your project is essential for making informed decisions.

Factors to Consider When Selecting Stainless Hex Nuts

When selecting stainless hex nuts for projects, several crucial factors come into play. The choice of stainless steel grade is paramount. Common grades like 304 and 316 have different corrosion resistance. Grade 316 is often considered superior, especially in marine environments. However, 304 is sufficient for many applications. Understanding the operational environment helps to make a more informed decision.

Size and thread pitch are also significant. Proper sizing ensures compatibility with bolts. According to industry reports, up to 30% of fastener failures stem from improper sizing. Tolerance standards can vary. Familiarity with both the American National Standards Institute (ANSI) and the International Organization for Standardization (ISO) helps in making the right choice. These standards provide guidelines for ensuring the perfect fit.

Finally, don’t overlook the finish of the hex nuts. While polished surfaces look appealing, they may not always be functional. Sometimes a plain finish offers better grip, reducing the risk of loosening. Each project is unique, and what works for one may not work for another. Consider the specific requirements of your application carefully. Failure to do so might lead to costly repairs or even operational downtime.

Choosing the Right Stainless Hex Nuts: Key Factors

Sizing and Thread Types of Stainless Hex Nuts

When selecting stainless hex nuts, pay close attention to sizing and thread types. Proper sizing is crucial for ensuring a secure fit. Measure the diameter accurately. Common sizes range from 1/4 inch to 1 inch. The hex nut should fit snugly on the corresponding bolt. If the sizes are mismatched, the connection may fail.

Thread types are another key factor. The two main options are coarse and fine threads. Coarse threads provide better grip in softer materials. Fine threads are ideal for applications requiring precision and vibration resistance. Test both thread types before making a final decision.

It's important to remember that installation can impact performance. Practicing with test samples can reveal issues you might overlook. Check for compatibility with other fasteners in your project. Avoid making assumptions. Patience during the selection process can save time and resources later.

Material Grades and Strength Ratings of Stainless Hex Nuts

When selecting stainless hex nuts for your projects, understanding material grades is crucial. Stainless steel is categorized in several grades, each offering unique properties. The most common grades are 304 and 316. Grade 304 is versatile and resistant to corrosion. However, it might not withstand harsh chemicals. Grade 316 is better suited for marine environments. It provides superior corrosion resistance.

Strength ratings also play a vital role in your selection. Each grade has different tensile strengths. For example, 304 hex nuts have a good balance of strength and ductility. Yet, when you need higher tensile strength, grade 316 is your best bet. Still, you should consider the specific application. Overestimating strength can lead to failure under pressure.

Keep in mind that not all projects are the same. Sometimes, opting for a lower grade may save costs without sacrificing too much performance. Evaluate your environment and requirements. A little reflection can prevent future issues. Understanding these details ensures you choose the right hex nuts for your project.

Common Applications for Stainless Hex Nuts in Various Projects

Stainless hex nuts are widely used across various projects due to their strength and resistance to corrosion. In construction, they secure beams and frames. In plumbing, they attach pipes tightly, preventing leaks. Many automotive assemblies rely on them as well. Their durability in harsh environments makes them ideal for outdoor projects and marine applications.

Using the right type of stainless hex nut is essential. For food processing or medical applications, certain grades are necessary. Some projects may require higher resistance to chemicals or extreme temperatures. It's crucial to assess the specific needs of your project. Mistakes can lead to failures, which can be costly.

Sometimes, choosing between hex nuts can be confusing. Not all sizes fit every bolt perfectly. A small oversight in measurement can result in loose fittings or structural weaknesses. Consider consulting guidelines or experts when in doubt. Making informed choices helps ensure the longevity of your project.