What is the Best Slitter Cutter Machine for 2026?

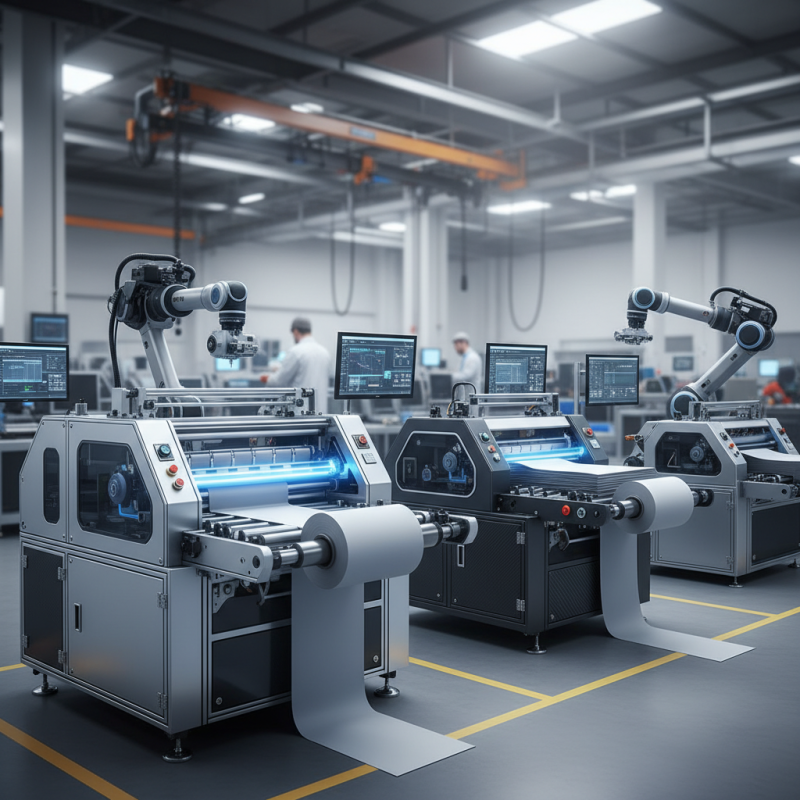

In the world of manufacturing, choosing the right Slitter Cutter Machine can be challenging. As industries evolve, so do the machines that support them. The year 2026 promises advancements in technology, making it essential to assess options carefully.

A quality Slitter Cutter Machine can greatly improve efficiency. It’s vital to consider features like precision, speed, and ease of use. Machines that offer versatility in cutting various materials are also worth exploring. However, not all machines are perfect. Some may have limitations or require frequent maintenance.

Potential buyers should reflect on their specific needs. Budget constraints can impact decisions significantly. Therefore, understanding the balance between cost and functionality is important. A well-informed choice can lead to increased productivity and less waste. In this fast-paced industry, what will you prioritize in your search for the best Slitter Cutter Machine?

Overview of Slitter Cutter Machines and Their Applications

Slitter cutter machines play a crucial role in various industries. They are commonly used in packaging, textiles, and paper. These machines can cut wide rolls into narrower strips. Precision is key. A good slitter cutter should provide consistent results.

Many applications require specific cutting techniques. For instance, in the textile industry, slitting machines can handle delicate fabrics. These machines must manage tension well. Any misalignment can lead to waste. This highlights the need for user training and machine maintenance.

Users often face challenges with adjusting settings. It can be tricky to find the right speed and blade angle. Therefore, operators need to practice. Testing different materials helps improve skill. Awareness of machine capabilities is vital. It influences production efficiency and quality.

What is the Best Slitter Cutter Machine for 2026? - Overview of Slitter Cutter Machines and Their Applications

| Model | Cutting Width (mm) | Max Speed (m/min) | Material Types | Applications | Features |

|---|---|---|---|---|---|

| Model A | 1500 | 300 | Paper, Film | Packaging, Labeling | Automatic Tension Control, High Precision |

| Model B | 1200 | 250 | Plastic, Foil | Cables, Electronics | User-Friendly Interface, Energy Efficient |

| Model C | 1800 | 400 | Paper, Textiles | Textile Industry, Printing | Quick Change Blade System, Compact Design |

| Model D | 2000 | 350 | Metal, Composite | Automotive, Aerospace | Precision Calibration, Multi-Cutting Capability |

Key Features to Consider in a Slitter Cutter Machine for 2026

When considering the best slitter cutter machine for 2026, specific features are vital. Efficiency is paramount. Reports indicate that slitter cutter machines with a productivity rate exceeding 30 meters per minute are becoming standard. Speed alone isn’t enough, though. Precision remains crucial as industries demand tighter tolerances.

Another key feature is versatility. A slitter cutter should handle various materials. According to recent industry studies, machines capable of cutting films, paper, and non-woven materials are in high demand. Not all machines perform equally well across these materials. Research shows that users often experience issues with inconsistent cutting quality when switching between materials.

Tips: Always look for machines that offer easy adjustments for different thicknesses. Certifications ensure reliable performance. Regular maintenance is essential to prevent breakdowns. Remember that the initial cost isn’t everything. Consider long-term savings from reduced waste or downtime.

Additionally, automation will be vital. Machines that integrate smart technology for monitoring performance are becoming essential. A report from the International Manufacturing Board suggests that 65% of manufacturers see automation as a game-changer. However, balancing tech and user training is challenging. A reliance on automation should not replace skilled operators.

Top Brands and Models of Slitter Cutter Machines for 2026

Choosing the best slitter cutter machine for 2026 requires careful consideration. Various factors influence your decision, including the materials you cut and the volume of your production. The latest models offer improved efficiency, cutting precision, and user-friendly features. They cater to different needs across various industries.

Key factors include blade design, cutting speed, and maintenance needs. Some machines may have innovative blade systems that enhance durability. Yet, certain user feedback highlights the complexity of operating these advanced models. Features intended for ease of use can be overwhelming for new operators. It's crucial to evaluate the learning curve before making a purchase.

In addition, consider the machine’s adaptability. It should handle diverse materials without frequent adjustments. However, not all models excel in versatility. Some may struggle with thicker materials. Gathering user reviews helps in identifying common pitfalls. Ultimately, investing time in research ensures you select the right slitter cutter machine for your specific requirements in 2026.

Technological Advancements Impacting Slitter Cutter Performance

The slitter cutter machine market is experiencing significant changes due to technological advancements. In 2026, new features will drive performance and efficiency. For instance, automation is becoming essential. Recent reports indicate that automated slitting machines can increase productivity by up to 30%. This transition to automation is crucial for meeting high demand.

Moreover, precision engineering is evolving. The introduction of better materials enhances blade durability. A recent industry study shows that machines with advanced carbide blades last longer and perform better. This can reduce maintenance costs significantly, up to 25% over time. However, not all manufacturers are keeping pace with these innovations.

Software integration is another critical trend. Enhanced control systems allow operators to customize settings quickly. This flexibility can lead to improved quality in cuts. Yet, the reliance on complex software may pose challenges for staff training. Some operators might find it difficult to adapt. Balancing technological upgrades with operator readiness remains a key issue. As we look ahead, these advancements will shape the best slitter cutter machines. The industry must continuously reflect on these challenges to fully leverage technological potential.

Comparative Analysis of Cost and Efficiency in Slitter Cutters for 2026

In 2026, selecting the right slitter cutter machine requires careful consideration of cost and efficiency. Manufacturers now prioritize advanced technology to optimize performance. These machines offer various cutting speeds, which directly impact production rates. However, higher speed does not always mean better efficiency. There are instances where slower machines produce cleaner cuts.

Cost analysis plays a crucial role in decision-making. Many businesses grapple with the balance between initial investment and long-term savings. Some slitter cutters are priced high but offer minimal operational expenses. Others might be cheaper upfront yet require costly maintenance. Understanding the total cost of ownership is vital.

Efficiency is not solely about speed. Features such as automatic setups can save time, reducing labor costs. But, device reliability is a key concern. Frequent breakdowns can lead to delays. Manufacturers often overlook these factors. It’s essential for operators to reflect on both the quantitative and qualitative details. The ideal choice should merge performance with practicality.