Ball Screw for Sale Top Tips for Buying the Best Quality?

When considering a "ball screw for sale," it is crucial to recognize the importance of quality and performance in precision machinery. According to a recent report by the International Association of Manufacturing Engineers, around 65% of manufacturing issues stem from using substandard components. This statistic emphasizes the need to prioritize quality over cost when selecting a ball screw.

Johnathan Carr, a leading expert in mechanical engineering, states, "Investing in high-quality ball screws is vital for operational precision and longevity." His insight reflects the industry's growing awareness of how critical these components are in achieving mechanical accuracy. Therefore, buyers should approach their purchase with a discerning eye, focusing on materials, load capacities, and manufacturer reputation.

Moreover, many buyers overlook the impact of maintenance and installation quality on performance. A poorly installed ball screw can lead to decreased machine efficiency, resulting in expensive downtime. Regular inspections and proper alignment are essential for maximizing the lifespan of these components. Reflecting on these factors, it becomes clear that making an informed choice in your ball screw selection can lead to significant long-term benefits.

Understanding Ball Screws: Types and Applications

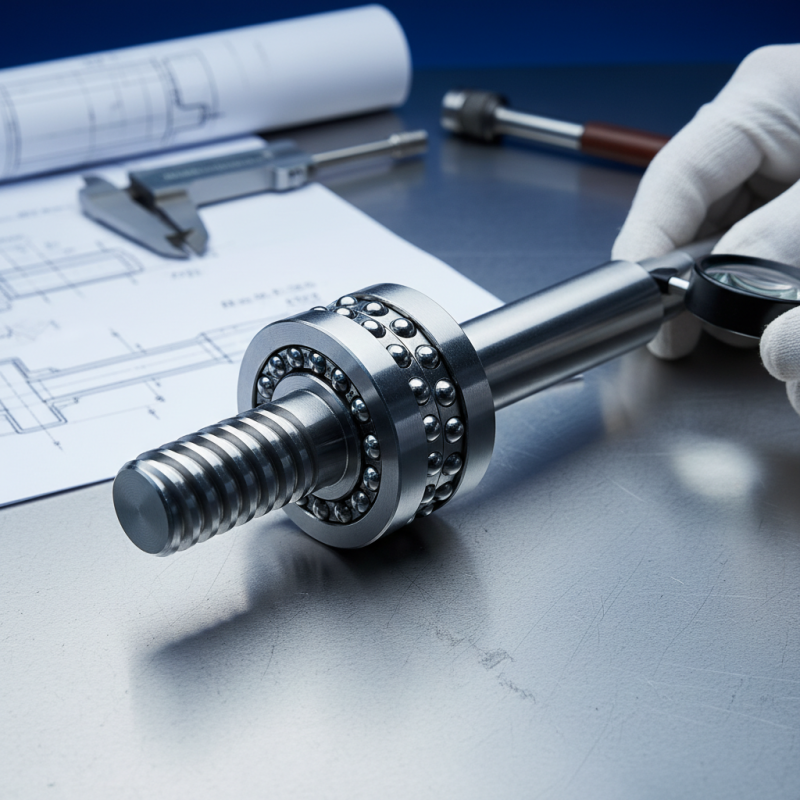

When it comes to ball screws, understanding the types and applications is crucial. Ball screws convert rotary motion into linear motion. They are widely used in machinery, robotics, and automation systems. This versatility makes them essential in modern engineering.

There are several types of ball screws. Some are self-lubricating, while others require manual lubrication. Each type has unique benefits and drawbacks. For example, self-lubricating screws may have less friction but can wear out quickly. Manual lubrication may require more maintenance, yet it can ensure a longer lifespan.

Consider where you will use the ball screw. In high-speed applications, precision and durability are key. However, for lower-speed projects, you might prioritize cost-effectiveness. Keep in mind that not all ball screws are created equal. Poor-quality options can lead to project failures. A clear understanding of your project needs will guide you toward making better choices.

Key Factors to Consider When Buying Ball Screws

When buying ball screws, several key factors directly impact your choice. Material quality is crucial. Look for high-grade steel or alloys. This ensures durability and longevity. A recent study found that the right materials can increase lifespan by 30%.

Precision is another vital aspect. Accurate dimensions lead to better performance. Small deviations can result in reduced efficiency and possible failure. It's advisable to use calipers to double-check measurements. Don't hesitate; ask for specifications from the supplier.

Tip: Always assess the load capacity. Higher loads may require reinforced designs. Think about the application’s demands. Consider backlash as well. It's important for maintaining accuracy.

Keep in mind that sourcing from multiple suppliers can be beneficial. Different manufacturers may offer varying quality levels. This can lead to tough choices. Sometimes, prices may not reflect performance effectively. Balance cost with quality demands.

Evaluating Quality: Certifications and Manufacturing Standards

When looking for a ball screw, quality is crucial. Certifications and manufacturing standards play a vital role in evaluating products. Numerous industry certifications indicate a manufacturer’s commitment to quality. Look for ISO certifications, as they signify adherence to international standards. These certifications assure reliable performance under various conditions.

Manufacturing processes also affect quality. Ensure that the ball screw is produced using precision machinery. This equipment can significantly influence the final product’s accuracy. Quality control measures should be in place during production. Inadequate quality checks can lead to flaws that compromise functionality.

It’s wise to reflect on your specific needs. Think about the application: speed, load capacity, and environmental conditions. Sometimes, opting for a less expensive ball screw can lead to unexpected issues. Consider the long-term benefits of investing in a high-quality component. Don’t rush your decision; instead, seek information and conduct thorough research.

Ball Screw Quality Evaluation

Maintenance Tips for Longevity of Ball Screws

Maintaining ball screws is essential for maximizing their lifespan and performance. Proper lubrication is critical. According to a report by the National Institute of Standards and Technology, well-lubricated ball screws can last up to 50% longer than those that are not. Regularly check the lubricant levels and ensure that the correct type is used. This helps reduce friction and wear on the screw.

Another factor to consider is alignment. Misalignment can lead to uneven wear. It can also cause vibrations, which may damage the ball screw. The Machinery's Handbook highlights that a misaligned assembly can decrease performance by 30%. Regular alignment checks can prevent these issues.

Routine inspections are also important. Look for signs of wear, such as noise during operation or a decrease in precision. Quick reactions to such indicators can prevent more significant problems. Industry studies show that proactive maintenance reduces downtime by up to 25%. Engaging in these practices helps ensure that ball screws perform optimally and serve their intended purpose effectively.

Ball Screw for Sale Top Tips for Buying the Best Quality

| Criteria | Importance Level | Tips | Expected Lifespan |

|---|---|---|---|

| Material Quality | High | Choose steel or stainless steel for durability. | 10-15 years |

| Load Capacity | High | Select based on the maximum load requirements. | 10-20 years |

| Precision | Medium | Look for tolerance ratings that meet operational needs. | 5-10 years |

| Manufacturer Reputation | High | Research manufacturers and read reviews. | N/A |

| Maintenance | High | Regular lubrication and inspection can extend lifespan. | Indefinite with proper care |

Comparing Prices: How to Find the Best Deals on Ball Screws

When searching for ball screws, comparing prices is essential. Start by researching various suppliers. Explore online marketplaces and local distributors. Note that prices may vary widely. Observe the material quality and specifications, as these impact performance and reliability.

It’s easy to get caught up in price alone. Focus on value instead. A cheaper option may seem attractive but could lead to problems. Examine warranty information and customer reviews. These details reveal a lot about reliability.

Consider reaching out to suppliers for bulk deals. Sometimes, negotiating can yield better prices.

Don't rush the decision-making process. Reflect on your specific needs first. Are you looking for precision, load capacity, or durability? Asking these questions helps clarify your choices. Finding the best deal isn’t just about price; it’s about ensuring quality and performance that meets your requirements.