2026 Top Heavy Equipment Innovations and Trends to Watch Out For?

In 2026, the Heavy Equipment industry is set to witness incredible innovations and trends. Experts predict significant advancements in automation, sustainability, and efficiency. John Smith, a renowned Heavy Equipment specialist, stated, "The future of our industry lies in integrating technology with conventional machinery."

New technologies are transforming heavy machinery. Electric excavators and hybrid dozers are now becoming commonplace. They not only reduce emissions but also lower operational costs. However, the transition is not without challenges. Many companies struggle to adapt to these new technologies. Training the workforce is essential but often overlooked.

Market demand is shifting towards smarter solutions. Remote monitoring and AI-driven analytics offer unprecedented insights. Companies that embrace these changes can gain a competitive edge. Yet, the rapid pace of innovation may leave some behind. The Heavy Equipment sector must strike a balance between tradition and modernity. In this dynamic landscape, reflection on past practices is critical for future success.

Key Technological Advancements in Heavy Equipment for 2026

The heavy equipment sector is set for significant technological advancements in 2026. Automation and smart technologies will lead the way. GPS and IoT will play crucial roles in improving efficiency. These features will help minimize human error and streamline operations. Operators will find their jobs changing as machines become more autonomous.

*Tip: Always stay updated on emerging technologies. Attend industry conferences and webinars for the latest insights.*

Moreover, sustainability will drive innovations. New engines will be more fuel-efficient and meet stricter emissions standards. Electric and hybrid models will become more common. However, adopting these technologies can be challenging. Companies must balance cost and benefits.

*Tip: Conduct a cost-benefit analysis before investing in new equipment. This will help in making informed decisions.*

Lastly, data analytics will transform how equipment is operated and maintained. Predictive maintenance will reduce downtime and extend machinery life. Yet, not all companies will adapt quickly. This could create a gap between early adopters and others. It’s essential to monitor both trends and competitors.

2026 Top Heavy Equipment Innovations and Trends to Watch Out For

| Innovation/Trend | Description | Expected Impact |

|---|---|---|

| Autonomous Machinery | Integration of AI and machine learning to enable equipment to operate without human intervention. | Increased efficiency and reduced labor costs. |

| Electric Equipment | Shift from diesel to electric engines to reduce emissions and improve sustainability. | Lower operational costs and environmental impact. |

| Telematics and IoT | Enhanced connectivity through sensors and data analytics for real-time monitoring. | Improved maintenance and operational efficiency. |

| Augmented Reality (AR) | Use of AR for training operators and enhancing productivity through real-time data overlay. | Faster training times and improved safety. |

| 3D Printing of Parts | On-site manufacturing of spare parts to reduce downtime and inventory costs. | Greater flexibility in repairs and maintenance. |

Sustainability Trends Shaping the Future of Heavy Machinery

The heavy machinery industry faces a pivotal shift toward sustainability. According to a recent report, 70% of companies are investing in green technologies. This commitment aims to reduce emissions and improve energy efficiency. Innovations like electric and hybrid heavy equipment are emerging, and they play a crucial role in this transformation.

In 2026, we expect to see an increase in biofuels and alternative energy sources. A survey highlights that 65% of industry leaders believe these will become mainstream. However, challenges remain. The availability of charging infrastructure for electric machines is still limited. Many construction sites have not adapted to these changes yet.

Safety regulations are also evolving, requiring new machinery to meet stricter standards. This adds complexity to the development process. While advancements in technology are impressive, they must align with sustainable practices. Companies must balance profitability with environmental responsibilities. Achieving this balance is the key to a greener future in heavy equipment.

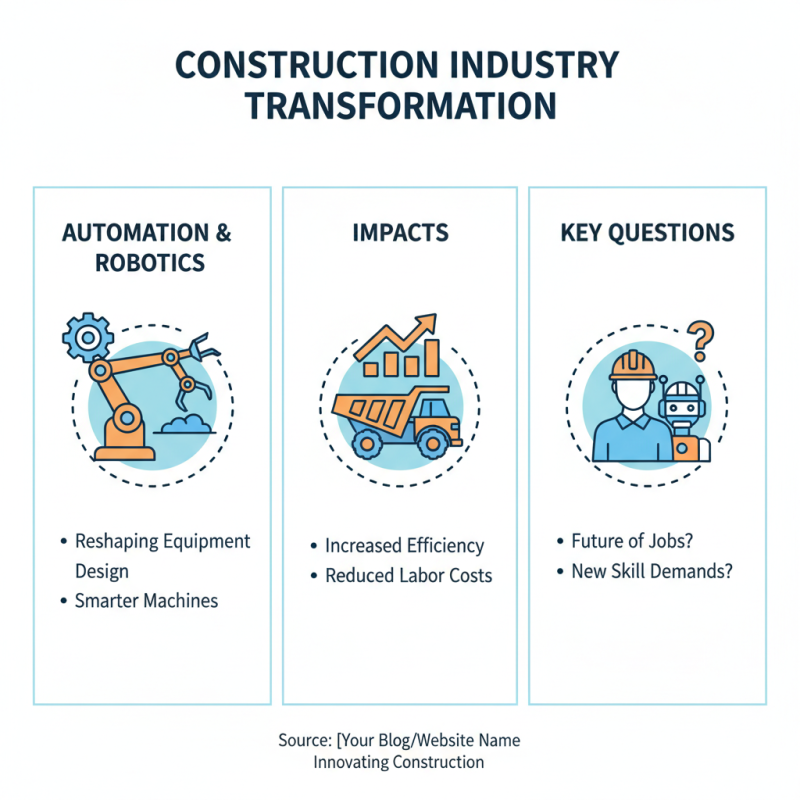

The Rise of Automation and Robotics in Construction Equipment

The construction industry is on the brink of a major transformation. Automation and robotics are reshaping how heavy equipment is designed and used. Machines are becoming smarter. They can perform tasks with minimal human intervention. This shift promises increased efficiency and reduced labor costs. However, it also raises important questions.

Automation reduces the need for manual labor, which can lead to workforce challenges. Skilled workers may find it hard to adapt to new technologies. Training will need to evolve to address these gaps. Small and medium-sized companies might struggle to keep up with the pace. Investment in automation can be daunting for them. Their concerns about job security can also hinder acceptance.

Moreover, while robotics can enhance productivity, they require significant maintenance. Ensuring these machines operate safely is crucial. Incidents of malfunction can lead to serious accidents on site. As construction companies embrace this trend, they must implement robust safety protocols. Ultimately, the rise of automation and robotics in heavy equipment carries both potential and peril.

Impact of Smart Technologies on Heavy Equipment Efficiency

The heavy equipment industry is experiencing a transformational shift thanks to smart technologies. Innovations such as IoT sensors and data analytics play a key role in enhancing efficiency. According to a recent industry report, companies using smart technologies can reduce downtime by up to 30%. This improvement is vital for maximizing productivity in a competitive landscape.

One exciting development is remote monitoring. Operators can track equipment performance in real-time. This capability allows for predictive maintenance, which can lower maintenance costs by 25%. Companies are recognizing that investing in smart technologies is no longer optional; it’s essential for staying relevant.

Tip: Regularly assess your current technology stack. Evaluate how smart technologies can fit into your operations.

The integration of automated systems also improves safety on job sites. However, some workers may resist these changes, fearing job loss. Ensuring proper training and communication is crucial. A report indicates that 50% of workers are concerned about automation. Addressing these fears is necessary for smoother transitions.

Tip: Foster a culture of continuous learning. Provide training sessions on new technologies for all employees.

2026 Heavy Equipment Innovations: Efficiency Impact of Smart Technologies

Evolving Safety Standards in the Heavy Equipment Industry

Safety in the heavy equipment industry continues to evolve. New regulations aim to protect workers from accidents. Equipment manufacturers are under pressure to enhance safety features. Rollover protection systems are now standard in many machines. But there's still room for improvement in training practices.

Innovations like augmented reality are gaining traction. Operators can visualize hazards before they operate machines. However, not all training programs incorporate these new technologies. Many workers still rely on outdated methods. This gap can lead to dangerous situations on job sites.

The push for better safety standards must prioritize real-world application. Collaboration between manufacturers, regulators, and operators is essential. While technology advances, human factors remain a challenge. Continuous feedback and assessments can bridge this gap. The future of safety in heavy equipment relies on proactive measures.

Related Posts

-

Top 10 Drum Handling Manufacturers from China at the 137th Canton Fair

-

How to Identify the Best Manufacturers for High Quality Material Handling Supplies

-

Ultimate Guide to Choosing the Best Material Handling Solutions for Your Business Needs

-

Understanding the Importance of Barrel Lifting Equipment in Modern Warehousing

-

5 Compelling Benefits of Choosing Vacuum Lifting Equipment for Your Business

-

7 Essential Tips for Choosing the Best Material Handling Equipment for Your Business