2026 Top Laboratory Sample Pulverizer Buying Guide?

In the ever-evolving world of laboratory equipment, choosing the right laboratory sample pulverizer is crucial. Dr. Linda Carter, a respected industry expert, once stated, “Selecting a pulverizer can significantly impact your research quality.” This perspective holds true as the right model ensures precise sample preparation, vital for accurate results.

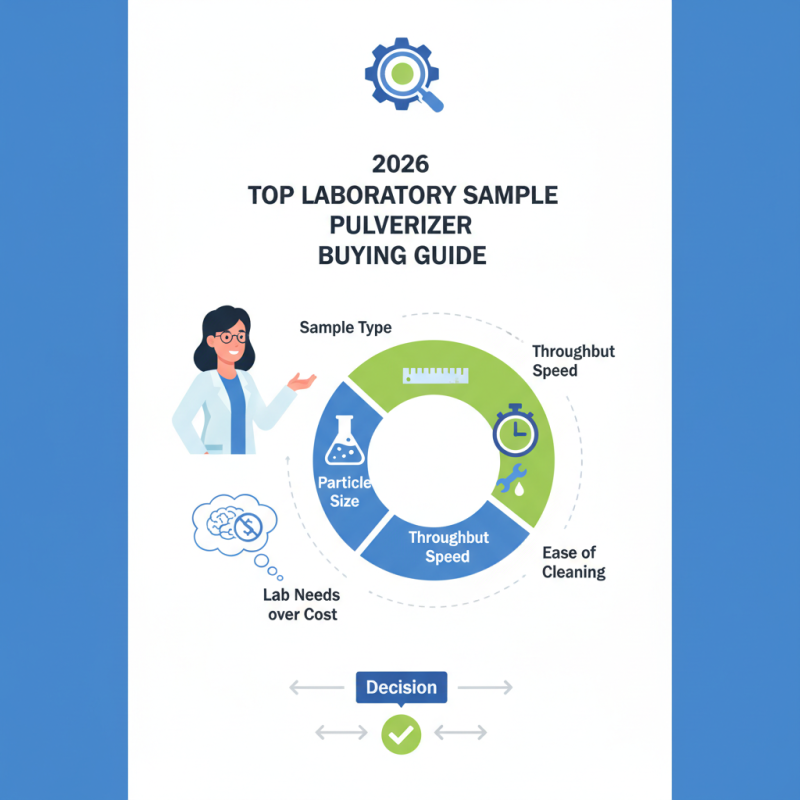

When evaluating different pulverizers, it's essential to consider various factors. The type of samples processed, the required particle size, and throughput speed all play immense roles. However, one must reflect on the specific needs of their lab rather than follow trends blindly. The right choice may not always be the most expensive model; it can be one that fits your lab's unique requirements.

Many laboratories overlook the importance of user-friendly features in a laboratory sample pulverizer. For instance, ease of cleaning can save valuable time. Ignoring these specifics can lead to operational inefficiencies and compromised results. Thus, careful consideration is necessary before making a final decision.

Key Features to Consider in a Laboratory Sample Pulverizer

When selecting a laboratory sample pulverizer, key features demand your attention. One crucial aspect is the material type. Make sure the pulverizer can handle the specific materials you intend to process. Different materials require different grinding mechanisms. This determines efficiency and outcome quality.

Power capability is also important. A powerful motor speeds up the grinding process, reducing sample prep time. However, too much power can lead to overheating, affecting durability. Consider the balance between power and heat management.

Tips: Always evaluate the size of the pulverizer. Compact models save space but may limit sample size. Larger machines handle more volume but require adequate lab space. Reflect on your lab’s size and workflow.

Another notable feature is the ease of cleaning. Efficient cleaning mechanisms save time and prevent contamination. A design that minimizes residue buildup is ideal. Ensure that all parts are accessible and washable. This will streamline your processes.

In the end, choosing the right pulverizer is a careful balance of features. Keep your lab's specific needs at the forefront. Don't rush the decision. Gather insights and reflect on all aspects before making your choice.

2026 Top Laboratory Sample Pulverizer Buying Guide

| Feature | Description | Importance |

|---|---|---|

| Material Compatibility | Ability to process various materials such as minerals, ceramics, or organic samples. | High |

| Particle Size Range | The range of particle sizes that can be achieved by the pulverizer. | Medium |

| Power Requirements | Specifications regarding the electrical requirements for operation. | High |

| Grinding Mechanism | Types of grinding mechanisms used (e.g., ball mill, disk mill, etc.). | High |

| Noise Level | The amount of noise produced during operation. | Medium |

| Ease of Cleaning | How easily the pulverizer can be cleaned and maintained. | High |

| Safety Features | Safety mechanisms to prevent accidents during use. | High |

| Portability | Weight and design attributes that affect easy transportation. | Medium |

Types of Laboratory Sample Pulverizers and Their Applications

Laboratory sample pulverizers are essential tools for material analysis. They come in various types, each designed for specific applications. For instance, the ball mill is favored for its versatility. It's effective for both hard and soft materials, providing fine powders needed for accurate analysis.

Another common type is the disc mill. This pulverizer excels in crushing and grinding brittle materials. Reports indicate that the disc mill can reduce samples to a size of 100 microns or less. This is particularly advantageous in geological and mining studies. However, achieving such precision requires careful calibration and maintenance.

Some laboratories opt for planetary mills. These instruments are known for their high-energy cominution. By applying intense pressure and friction, they can produce a uniform particle size. However, they often require additional energy and can wear down quicker than other types.

Choosing the right pulverizer depends heavily on your sample type and desired outcome. It's important to analyze the strengths and weaknesses of each option. Sometimes, laboratories spend excessively on equipment that doesn’t meet their needs, leading to unsatisfactory results. Always consider your lab’s specific requirements before making a purchase.

2026 Laboratory Sample Pulverizer Types and Their Applications

Factors Affecting Performance and Efficiency of Pulverizers

When selecting a laboratory sample pulverizer, several factors can greatly impact its performance and efficiency. The material type being processed plays a critical role. Harder materials often require more robust equipment. Conversely, softer materials may not need such heavy-duty machinery. Understanding the nature of the samples helps in choosing the right pulverizer.

Another essential aspect is the grinding mechanism. Different pulverizers employ varied methods, including impact, compression, and shearing. Each mechanism has its strengths and weaknesses. For instance, impact pulverizers might excel in speed but can generate heat, potentially damaging sensitive samples. It’s crucial to assess how these characteristics align with your specific application.

Furthermore, the adjustment options available in a pulverizer can affect output quality. Some machines offer precise control over particle size, while others may have limited settings. Reflecting on past experiences using different models can reveal the value of this feature. Observing how each unit performs can provide insights into optimizing your choice. Often, a model might seem efficient but lacks the versatility needed for various materials. Thus, analyzing your specific requirements is key.

Budget Considerations: Cost vs. Quality in Pulverizers

When considering the purchase of a laboratory sample pulverizer, budget plays a crucial role. Many professionals face the dilemma of balancing cost and quality. A recent industry report indicated that nearly 70% of laboratories prioritize quality over price. However, this can lead to overspending on equipment that may not meet their specific needs.

The key is to identify what features matter most. Basic models can start around $1,000, while high-end options may exceed $5,000. Yet, some mid-range pulverizers perform comparably to premium brands. A study published in the Journal of Lab Equipment revealed that 40% of users were satisfied with models priced between $2,000 and $3,000. It's essential to conduct thorough comparisons and weigh the long-term benefits against upfront costs.

Not every high-priced machine delivers the expected results. In fact, 30% of survey respondents reported dissatisfaction with their expensive purchases. This suggests that value isn't solely determined by price. Factors like ease of use, maintenance costs, and durability must also be included in the evaluation. Careful analysis can prevent unnecessary expenses and ensure a better purchase.

Top Brands and Models for Laboratory Sample Pulverizers in 2026

Selecting the right laboratory sample pulverizer can be a daunting task. In 2026, various models stand out in terms of performance and reliability. These machines aim to provide consistent particle size reduction for diverse materials. A solid choice ensures precision in sample preparation. However, not all models meet expectations. Variations in design often lead to unexpected results.

When exploring top brands, be aware of specific features. Some provide variable speed controls, while others focus on durability. A model that vibrates excessively may compromise the material's integrity. Additionally, maintenance is key. Frequent wear on blades can hinder efficiency. It’s crucial to prioritize regular checks to sustain performance.

User feedback plays a vital role in decision-making. Take note of real-life experiences to gauge reliability. Some users report issues with noise levels, which can disrupt workflows. Balancing performance and comfort is essential. In pursuing the perfect pulverizer, it’s wise to stay informed about new developments in the field. Keeping an open mind helps refine choices.